16

Package Size 8000.00cm * 1500.00cm * 3000.00cm Package Gross Weight 5000.000kg Product Description 16-18mm PP Hollow She

Basic Info.

| Model NO. | SJSZ65/132 |

| Board Layers | Single Plate |

| Screw No. | Single-screw |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008 |

| Customized | Customized |

| Condition | New |

| Name2 | Plastic PP Hollow Template Extrsuion Machine |

| Name3 | PP Sheet Making Machine |

| Name1 | Plastic Extruders |

| Type | Type |

| Name6 | PP Hollow Sheet Extrusion Line |

| Name7 | PP Board Production Line |

| Name5 | Building Templates Making Machine |

| Name4 | Plastic Machinery |

| Raw Material | PP Pellet |

| Usage | Wide Usage |

| Name | PP Sheet Extrusion Line |

| Extruder | Single Screw |

| Prcessing Type | Extruding Machine |

| Finial Product | PP Sheet |

| Output (Kg/H) | 350 - 450 |

| Transport Package | Plastic Film or Wooden Case |

| Trademark | GeGao |

| Origin | China |

| HS Code | 8477209000 |

| Production Capacity | 60 Sets/Year |

Packaging & Delivery

Package Size 8000.00cm * 1500.00cm * 3000.00cm Package Gross Weight 5000.000kgProduct Description

Product Description

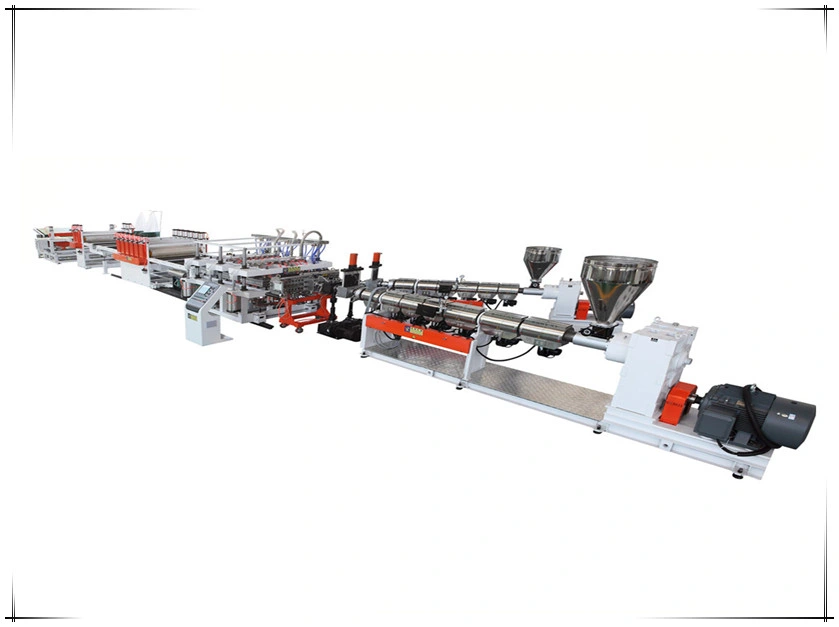

16-18mm PP Hollow Sheet Board Making Machine Plastic PP Plastic Sheet Production Line Extrusion Machine

The production line can use PP raw materials and adopt a single-screw extruder to produce three-layers hollow sheets. The quality and specifications of the produced plates meet the requirements of the demanding company.Pp Hollow plastic formwork is a kind of energy-saving and green environmental protection product, pp plastic combined with macromolecule nano-technology. Plastic formwork is a new product after wood formwork, composite steel formwork, bamboo-wood bonding formwork and all-steel large formwork. Hollow plastic formwork is energy saving and environmental protection,and can completely replace the traditional steel formwork, wood formwork, square wood, What's more, its amortization cost is very low

Extrusion Machine

| Drive system | Motor power | 132(kw) |

| Work way | Ac motor, elastic coupling connection | |

| Reducer | GUOMAO , Changzhou | |

| Debugging mode of main drive motor | Frequency control | |

| Features | Hard tooth surface reducer.Gear using high - strength low - carbon alloy steel carburizing from pitch, tooth surface hardness of HRC58-62 |

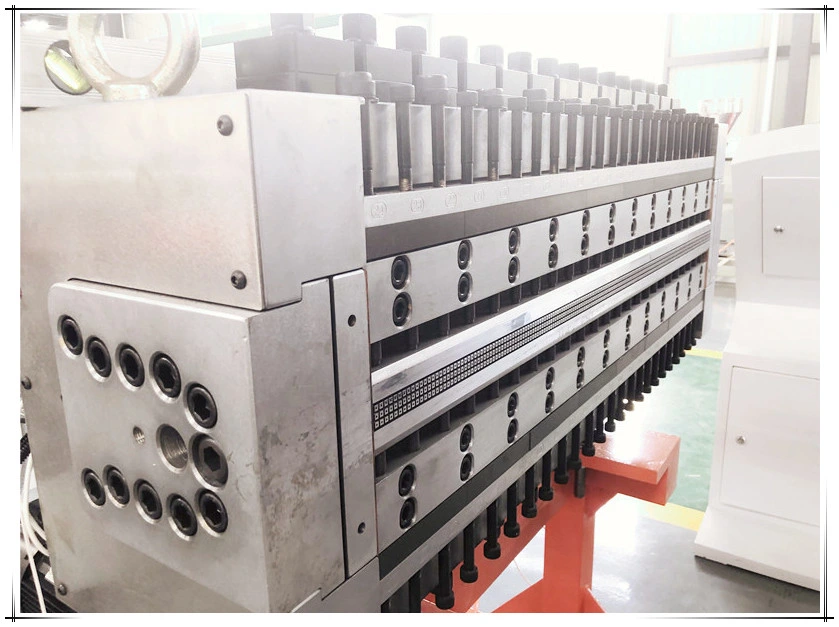

Mold Part

| Heating zones | ≥7zones |

| Heating power | 30kw |

| Mould structure | 15-20mm, width of product :1220mm |

| Inside treatment | The surface is treated with chrome plating polishing. Polishing coating thickness is greater than 0.06MM. |

Forming Part

| Structure | Horizontal placement, divided into two parts |

| Number of calibration mould | 6 sets |

| Effective width | 1220mm |

| Material | High quality steel forging processing |

Cooling bracket

| Structure | Integral square pipe frame |

| Length | 1.5m (Total length of first and second : 3m) |

| Rollers | Aluminum roller, surface anodized treatment, polishing, no holding phenomenon |

| Roller size | ф70×1100mm |

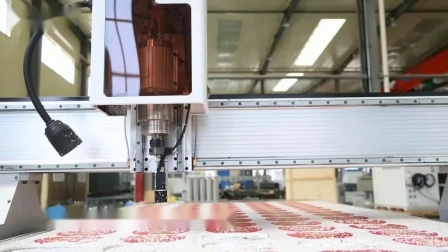

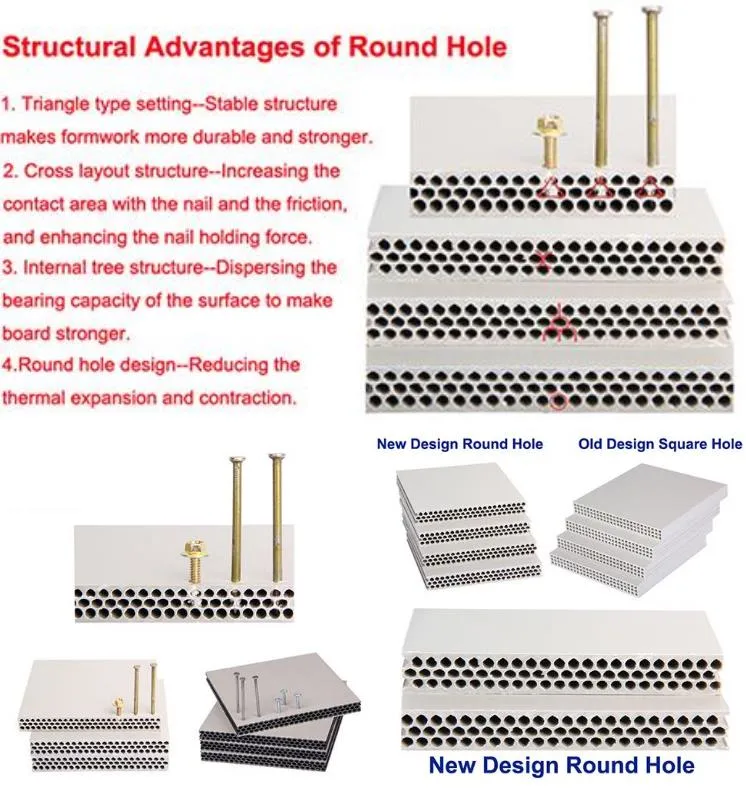

Detailed ImagesAdvantages 1. Light weight, high strength, high hardness, impact resistance, wear resistance. 2. Surface is smooth, bright and clean;Concreting and forming effect is good for pp hollow sheet making machine. 3. No absorption of moisture, no deformation, no mildew;Long-term immersion stratification in the water, no bubbles, sheet size stability, especially suitable for underground and dampenvironment.4. Good toughness. pp hollow sheet making machine could be used as cambered special-shaped formwork.5. Acid and alkali resistance, corrosion resistance; pp hollow sheet making machine is very suitable for the engineering application in coastal areas, mine, as well as seawall. pp hollow sheet making machine needs not do any preservative treatment both in using and storing the formwork, which do not pollute the concrete surface. 6. The reusable time for pp hollow sheet making machine can reach more than 60 times, long service life.7. Waste products can be recycled and reprocessed, making full use of waste materials. This property can greatly reduce the project cost compared with wooden formwork and bamboo formwork. 8. Environmental protection and energy saving, no pollution. No any poisonous or harmful gas.9. Demould easily. No need brushing release agent, only tapping, the plywood formwork price will fall off. Shorten working hours and speed up the construction schedule efficiently.10. Easy to process. Sawing, drilling and nailing are all available. pp hollow sheet making machine can be combined vertically and horizontally optionally.11. Easy to remove. Removing is convenient, quick and safe, and the supporting is also easy to operate,advantageous to the organization construction, effectively improving the construction schedule.

Main Technical Specification

| Model | GRS120/30 | GRS150/35 |

| Material | PP Modified Material | PP Modified Material |

| Products width | 915/1220mm | 915/1220mm ,915x2 |

| Products thickness | 15-20mm | 15-20mm |

| Capacity(Max) | 350-450kg/hour | 500-600kg/hour |

| Extruder specification | 120/35 75/35 | 150/35 90/35 |

Packing&Shipping

1.For the loose cargo we will packing by wooden box2.For the full container loading we are packing the machine by film and some on pallet accordingly3.We can shipping the goods by air or by sea4.We will send pictures of cargo loading to our client to check and keep recording5.We can send cargo to client's warehouse to loading

Our Services :

Company Introduction

Our company occupies an area of 20,000 square meters, and we own 7,000-square-meter international standard factory building.Ourcompany is a professional comprehensive plastic machinery manufacturer which integrates researching, developing and manufacturing together. We have obtained the ISO9001 certificate.We produce various plastic machines, such as single-screw-stem extruders, conedouble -screw-stem extruders, high-speed mixers, sets of production lines of pipes, plates, sheet materials and various kinds of auxiliary machines. They are well sold in Chin and about 30 foreign countries, such as Russia, Malaysia, Lebanon, Myanmar and South Africa. They are praised by masses of our consumers.

FAQ

Q:Are you machinery factory or trading company?

We are machinery factory

Q:If we have very special request for the production line,could you help me to do the design?

Experienced mechanical designer customized-design provided.

Q:How can we visit your company and machines?

We are located in Zhangjiagang City which is about 2.5 hours nearby Shanghai Airport.If customer want to visit our factory,we will

pick up you at the airport.

Q:What`s the payment method?

T/T, L/C, etc

Q:How long is the warranty?

12 months

Q:How long is the delivery time?

Under normal conditions, products are delivered within 45 working days.

OUR EXHIBITION :

Send to us