Concrete Plastic Plywood Sheet PP Hollow Plastic Bofu Block Construction Formwork Tepmplate Corrugated Board Making Extruder Machine

Concrete Plastic Plywood Sheet PP Hollow Plastic Bofu Block Construction Formwork Tepmplate Corrugated board Making Extr

Basic Info.

| Model NO. | SJ120/150 |

| Computerized | Computerized |

| Customized | Customized |

| Condition | New |

| After Sale Service | Life Long with Professional After Sale Team |

| Control System | PLC Control System or Knob-Operated System |

| Contactor | Schneider |

| Raw Material | PP Granule |

| Machine Color | as Request |

| Inverter | ABB |

| Button | Schneider |

| Intelligent Temperature Controller | Omron |

| Material | Stainless Steel |

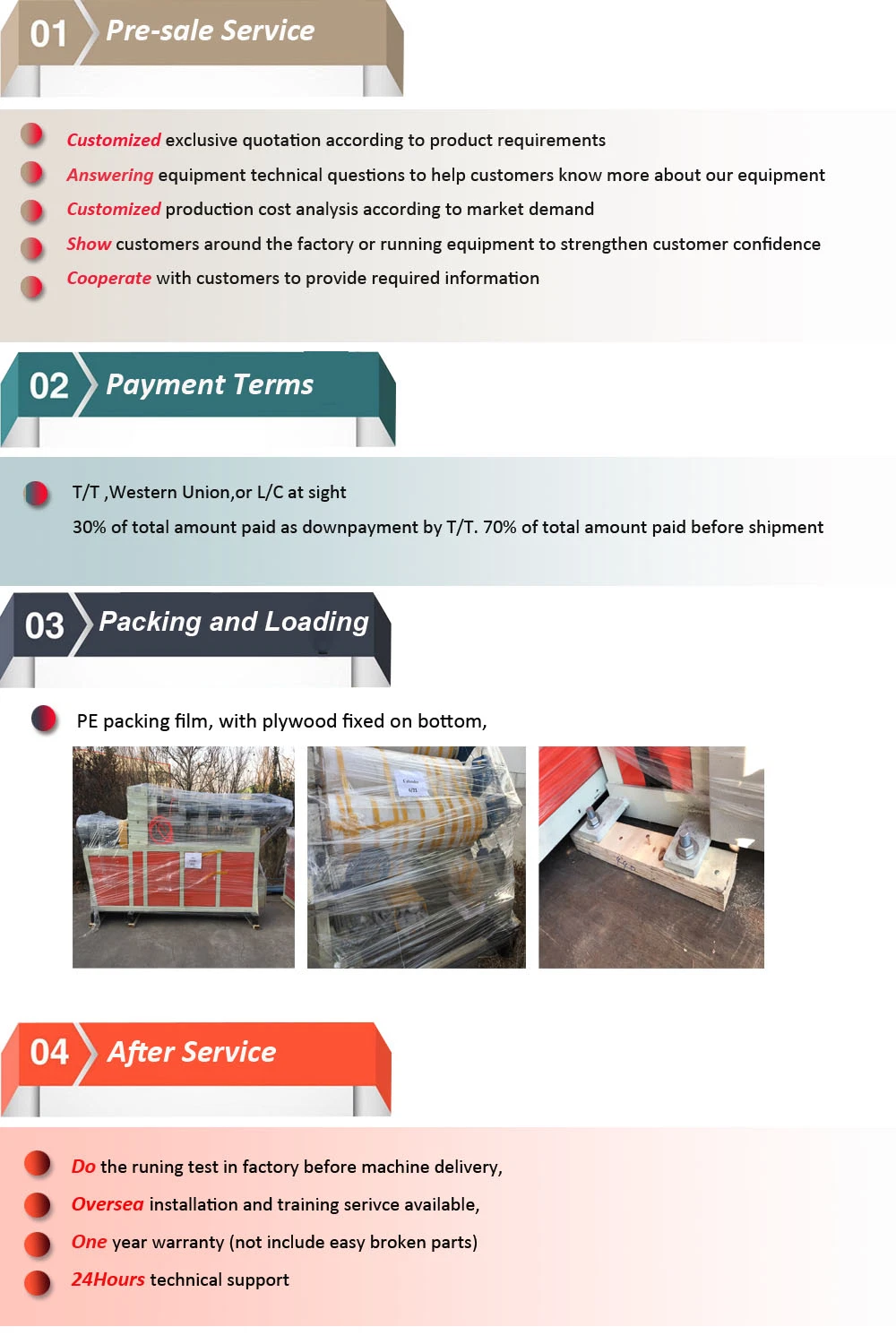

| Transport Package | as Export Standard for Plastics Machine |

| Specification | ISO9000 CE |

| Trademark | qdsuke |

| Origin | Qingdao, China |

| HS Code | 84778000 |

| Production Capacity | 25sets/Year |

Product Description

Concrete Plastic Plywood Sheet PP Hollow Plastic Bofu Block Construction Formwork Tepmplate Corrugated board Making Extruder MachineHollow Plastic Building Formwork is a kind of energy-saving an environment protecting product. The material is PP plastic combined with macromolecule nano-technology. It is a new product after wood formwork, composite steel formwork, bamboo wood bonding formwork and all-steel large formwork. It is energy-saving and environment protecting and can completely replace the traditional steel formwork, wood formwork, sqaure wood and further more its amortization cost is very low.Width: 819-1220mm, Thickness: 12mm, 15mm,18mmFormwork/Tempalte Advantages:No.1. Smooth and clean.The splicing of the formwork is strict and smooth, and the surface degree and finish of the concrete structure after demoulding exceed the technical requirements of the existing clear water formwork.No.2. Portable and easy to install.Light weight, strong process adaptability, can saw, planer, drill, nail, can be composed of any geometric shape, to meet the needs of various shapes of building die.No.3. Simple stripping.Concrete does not stick to the surface, no need of demoulding agent, easy demoulding, easy to remove ash.No.4. Stable weather resistance.High mechanical strength, in - 20 ºC to + 60 ºC temperature conditions, contractive, not wet bilge, no crack, deformation, stable size, alkali resistant anticorrosive, waterproof, flame retardant from rat pest control.No.5. Beneficial to maintenance.Templates do not absorb water, no special maintenance or storage.No.6. High variability.Types, shapes and specifications can be customized according to the requirements of construction projects. No.7.Reduce costs.More times of turnover, plane mold turnover more than 50 times, column and beam mold not less than 40 times, low cost.No.8. Energy saving and environmental protection.Scrap and waste templates can be recycled, zero waste discharge.

| Machine List | |||

| No. | Name | Qty. | Remark |

| 1 | Screw loader for SJ120/35 extruder | 1 | |

| 2 | Vacuum Loader for SJ75/35 | 1 | |

| 3 | SJ 120/35 single screw extruder | 1 | For the middle layer |

| 4 | SJ 75/35 single screw extruder | 1 | For the surface layer |

| 5 | Screen Changer1 | 1 | For SJ120/35 Extruder |

| 6 | Screen Changer2 | 1 | For SJ75/35 Extruder |

| 7 | Metering Pump1 | 1 | For SJ120/35 Extruder |

| 8 | Metering Pump2 | 1 | For SJ75/35 Extruder |

| 9 | Distributor for 3 Layers | 1 | |

| 10 | 1000mm Extrusion Mould | 1 | |

| 11 | Vacuum Calibration Table | 1 | 3 Groups Calibration Mould |

| 12 | Vacuum System | 1 | |

| 13 | Cooling Bracket (Forward) | 1 | 3000mm |

| 14 | Haul-off Unit (Forward) | 1 | High Quality Rubber Roller |

| 15 | Cooling Bracket (Backward) | 1 | 3000mm |

| 16 | Haul-off Unit (Backward) | 1 | High Quality Rubber Roller |

| 17 | Cutter | 1 | |

| 18 | Staker | 1 | |

Name: SJ120/35 Single screw extruder Technical parameters:a.Main motor : Siemens Brand.b.Siemens PLC control systemc.Screw barrel: 38CrMoAl, hardness Hv950 or more , high-efficiency and long service life.d.Scew structure : Great plasticzing effect , energe saved 20% Name: Extrusion mould

Technical parameters:

a.Unique die structure for hollow products using core molding optimized flow path through computer simulation to ensure uniform and stable flow,

b.Independent air flow control system to quickly balance the airflow in a short time to obtain a stable production .

c.Fine polishing of the cavity , lip and flowing channel.Name: Forming machine

Technical parameters:

a.The module is a one-time die-casting molding ,

b.Module material: LY12 high quality aluminum

c.Advanced machine center, one-time clamping of the module,

d.Four cylinder lift more stable. Name:Haul-off Roller

Technical parameters:

a.High quality rubber on the surface

b.Surface shore hardness 65-70,

c.Roller thicknee is more than 18mm

d.Increase the diameter of shaft heads and bearings ensure stable operation of thick board.

e.Double-row chain drive,forward and backward roller transmission coefficient is consistent .

| cross moving motor power cutting motor cleaner | 2.2kw 3Kw 1 set |

| longitudinal move | cylinder drive |

| length of transmission unit | 3m |

| motor power | 0.75kw |

Why Choose Us?

Strong StrenthFounded in 2002.20000 square meters factoryOver 50 workers Rich ExperienceOver 500 lines exportedSell to over 20 countriesCover all of extrusion products Professional SupportMachine & Specification MakingDetails infos classficationPicture & videos sharingFormula & operation support Good After Service Full set of drawings Full set of operation manualFree running test Free online technical support

Send to us