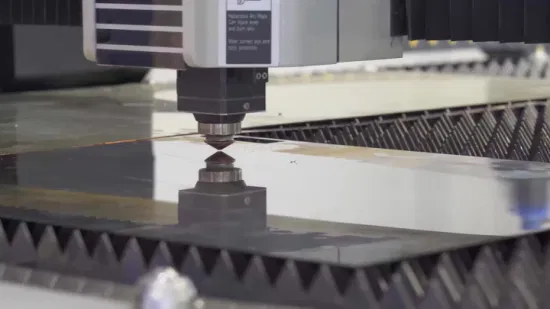

Factory Outlets 3/4/5 Axis CNC Machine Center Machine Tools Vmc1160 CNC Milling Machine

Overview Product Description The machine tool is of C-type structure, mainly composed of table, column, saddle, base, sp

Overview

Optional Accessories

Basic Info.

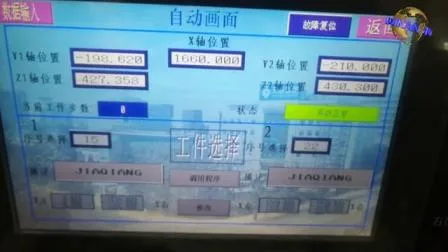

| Model NO. | BF-V11 |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.03~0.04(mm) |

| Performance Classification | High-End CNC Machine Tools |

| Certification | CE, ISO 9001 |

| Condition | New |

| Spindle Motor | 15/18.5kw |

| Spindle Speed | 12000rpm |

| Rapid Feed | 30m/Min |

| Rotary Table | 4 Axis / 5 Axis Optional |

| Table Size | 1200X600mm |

| Weight | 7000kg |

| Controller System | Fanuc / Mitsubishi / Siemens |

| Model | Bf-V11 |

| Product Name | Linear Guideway Vmc |

| Transport Package | Wooden Box |

| Specification | 3200x2810x3290mm |

| Trademark | Baofeng |

| Origin | China |

| HS Code | 8457101000 |

| Production Capacity | 1000sets / Year |

Product Description

- Main structure

- Machine design

- Base

- Column

It adopts the widened and large-span herringbone design to increase the rigidity of the body and enhance the torsional and bending resistance. At the same time, it enlarges the contact surface with the base for more stable processing.

- Worktable

- Saddle

The saddle is designed with the double ribbed structure to ensure the best rigidity.

Product Parameters| Travel | X-axis | mm | 1150 |

| Y-axis | mm | 660 | |

| Z-axis | mm | 650 | |

| Spindle nose to table | mm | 130-780 | |

| Spindle center to column | mm | 723 | |

| Worktable | Table size | mm | 1250x650 |

| Maximum load on table | kg | 900 | |

| T-slot | No. | 6-18x100 | |

| Controller | Fanuc System | 0i-MF(5) plus | |

| Spindle | Driving type | Direct drive | |

| Spindle speed | rpm | 12000 | |

| Spindle taper and specifications | BBT40 | ||

| Spindle motor power/torque (S2-15min S3/S6-25%) | Kw/Nm | 15/95.5 | |

| 3 axis motor | X/Y/ Z axis motor power | kw | 3.0/3.0/3.0 |

| X/Y/ Z axis motor torque | Nm | 20/45 | |

| X/Y/Z rapid feed | m/min | 36/36/36 | |

| Machine accuracy (X/Y/Z) | Positioning accuracy(bi-direction) | mm | 0.003/300 |

| Repeat positioning accuracy | mm | 0.002/300 | |

| Tools | Max.tool length | mm | 300 |

| Max.tool weight | mm | 7 | |

| Tool magazine capacity | 24 | ||

| Max.tool(full) | mm | 80 | |

| Max.tool Dia.(without adjacent tools) | mm | 150 | |

| Tool change time | Sec. | 1.75 | |

| Pull stud angle | deg. | BT40/45° | |

| Tool selection method | Proximity tool selection | ||

| Machine | Power requirement | KVA | 25 |

| Min/Max.air pressure | Kg/cm² | 5-7 | |

| Coolant tank capacity | L. | 350 | |

| Floor space requirement | mm | 3200x2810 | |

| Dimension | mm | 3290 | |

| Weight | Kg | 7000 |

| No. | Item | Remark |

| 1 | 4th axis/5th axis rotary table | |

| 2 | BT40-30T tool magazine | |

| 3 | Chain Chip conveyor | |

| 4 | Oil mist collectors | |

| 5 | CTS system |

Send to us