Tz

Basic Info.

| Model NO. | TZ-850B |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.01~0.02(mm) |

| Performance Classification | High-End CNC Machine Tools |

| Certification | CE |

| Condition | New |

| Spindle | Dejiu Taiz/ Taiwan |

| Screw Bearing | P4NSK/ Japan |

| Ball Screw | Yintai or Shangyin/ Taiwan (C3) |

| Spindle and Three-Axis Servo Motor | Mitsubishi/ Japan |

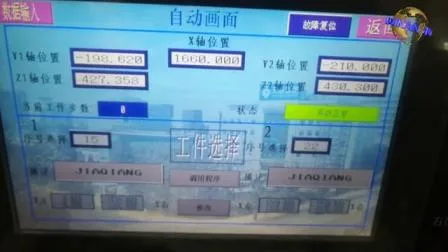

| CNC System | M80b Mitsubishi/ Japan |

| Transport Package | Plywood Case |

| Specification | 2400*2250*2650 |

| Trademark | TAIZ |

| Origin | China |

| HS Code | 8457101000 |

| Production Capacity | 2000 Sets Per Month |

Product Description

Product Description

TAIZ high-speed drilling and tapping machining center series products are based on the world's most popular and advanced flexible machine tool design concept development, mainly used for the processing of non-ferrous metals, 3C industry, communication cavity, aluminum substrate drilling, tapping processes.Can achieve drilling, milling processing, fast moving speed, high spindle speed.The efficiency and quality of drilling and tapping is more than 10 times that of ordinary machining centers, and it is the most ideal processing equipment for customers in 3C, communication cavity and other industries.

| Model | TZ-850B | |

| Worktable size L*W | (mm) | 1000x500 |

| Work table Max. loading | kg | 400 |

| T-slots size (N×W×D) | mm | 5x18x90 |

| X/Y/Z axis travel | mm | 800/500/420 |

| X/Y/Z axis feed speed | m/min | 48/48/48 |

| X/Y/Z axis motor | kw | 2/2/3 kw |

| X/Y/Z axis linear Guide | mm | 35/35/35 |

| Spindle taper | BBT30 | |

| Max. spindle speed | rpm | 20000 |

| Spindle motor power | kw | 5.5 |

| Distance from spindle nose to workbench | mm | 150-570 |

| A.T.C capacity | pcs | 21 |

| Positioning accuracy (X/Y/Z) | mm | ±0.005/300 |

| Re-positioning accuracy(X/Y/Z) | mm | ±0.003/300 |

| Machine weight | kg | 4200 |

| Machine size (L*W*H) | mm | 2400*2250*2650 |

| Main Parts | Branch/ Origin | |||||

| CNC System | M80B Mitsubishi/ Japan | |||||

| Spindle and three-axis servo motor | Mitsubishi/ Japan | |||||

| Spindle | Dejiu TAIZ/ Taiwan | |||||

| Ball screw | Yintai or Shangyin/ Taiwan (C3) | |||||

| Screw bearing | P4NSK/ Japan | |||||

| Rail | Yintai or Shangyin/ Taiwan (P) | |||||

| A.T.C capacity | TAIZ or Deda/ Taiwan | |||||

| Body casting | High density and high strength resin sand cast iron | |||||

| Coupling | R+W\NBK / German | |||||

| Electrical components | Franch | |||||

| Handwheel pulse | East Test/Internal Security Control / Janpan | |||||

| Pneumatic components | Taiwan AirTAC/ Japan SMC | |||||

General Description

The machine ADAPTS to the development trend of precision and high efficiency in the processing industry, and processes products such as electronic communications and textile parts with high efficiency and high precision to meet the most challenging processing requirements of various industries. The machine tool fully adopts the latest finite element simulation optimization design method, which is comprehensively optimized on the basis of the overall strength and stiffness of the machine tool to achieve the best dynamic machining performance. It is a representative and model of modular design and ergonomic design of international processing equipment.

Entire Distribution

Three axis straight slide, full support design.

The main parts are made of the same casting by the same manufacturer of Dema Brothers. High strength, high density resin sand impregnated casting.

Castings are calculated and analyzed by computer finite element analysis.

21-tool clamping arm tool library, tool change time up to 2.4 seconds.

Main parts of equipment

(1) Base

Large-span heavy base, guide rail specifications are 1.2 times greater than the same industry, effectively disperse gravity and processing capacity; Short saddle overhang greatly improves dynamic accuracy; The Y-axis motor rear design also helps to reduce the distance between the operator and the table, suitable for upper and lower workpieces, and greatly improve the processing convenience (as shown below).

(2) Uprights

(a) The herringbone column is more stable and more convenient to maintain than the one-column column.

(b) The design of the herringbone structure bed gold protection and chip removal system is more mature to avoid the installation of sheet metal water leakage from the mechanical structure.

(c) The use of high-strength screws to fix, effectively improve the rigidity of the column, avoid vibration during processing, and be more stable during heavy cutting.

(d) The shaft slint-bone structure is thickened at the same time, which greatly improves the rigidity of the bed, makes the processing more stable, and extends the service life of the machine tool.

(3) Headstock

The optimum contact ratio between the headstock and the column, coupled with the short nose-end Taiwan spindle, results in greater chip cutting capability for Taijing machine tools. Can complete drilling, milling, tapping, boring and other processes.(4) Precision spindle with high precision, high performance and high stability

(a) The spindle set is made in Taiwan. The main shaft grab tool is based on the butterfly spring on the main shaft, and the tension is applied to the pull nail of the tool handle through the four-jaw broach mechanism, which is closely matched with the taper hole of the main shaft to realize the grab tool.

(b) The use of low inertia spindle motor, short acceleration time, improve tapping speed and quality. Spindle direct drive, with spindle orientation function.

(5) Machine tool protection

The lathe bed guide rail (XY axis) adopts stainless steel telescopic sheet metal; The column guide rail (Z axis) adopts organ type and armor type protection; The machine is fully enclosed to prevent iron filings and coolant from splashing, so that the operator can work in a safe and comfortable environment.

(6) Power distribution

In addition to the mechanical design, Taijing machine tools also pay attention to the electrical design, the CNC system uses a unique optical fiber communication mode, which greatly improves the speed of data communication, and greatly reduces the number of wiring, so that the electrical cabinet is cleaner.

• Taiz CNC machine center integrates the function of milling, drilling and tapping• CNC Machining for various size of the metal profile, such as aluminum, steel, copper and non-metal materials

• CNC Vertical Machine tools is widely used in industries of 3C electronics, rail transportation, aerospace, liner module guide rail and etc.

Excellent processing conditions and good production environment

Imported horizontal machining center, vertical machining center, CNC boring machine (rotating table) and gantry guideway grinding machine, effectively ensure the accuracy of the workpiece, greatly improve the assembly accuracy, and the durability of the accuracy.

Advanced detection methods

Positioning accuracy test and best correction with laser, using strict German VDI3411 inspection specification (5 times each)

Rigorous machining testing

Each machine tool must go through a strict processing side test before leaving the factory to ensure that it can accept the test of actual processing and meet the corresponding processing accuracy requirements.

Guangdong Taizheng Intelligent Equipment Co., Ltd. was established in June 2010,is a set of intelligent equipment research anddevelopment, production, sales and service in one of the national high and new technology enterprise, the product has the high speeddrilling iron machining center, vertical machining centers, horizontal machining center, gantry machining center, pentahedron mach-ining centers and other series of precision machining equipment. After years of development, it has become one of the largest machinetool manufacturers in Taiwan and Mainland China.

Company since its inception,adhere to the "diligence, quality, innovation, win-win"concept of value, constantly explore innovative, whole image into the pursuit of the top performance of the machine, always held firm to provide clients with reasonable prices,excellent quality of machinery, each machine tool design and manufacture of machine with high precision, high performance, nighefficiency, long life as a standard, It has shaped the brand of TaiZheng machine tool and become the symbol of high quality workingmachine.