Basic Info.

| Model NO. | LXD2S-CNC-300 |

| Tenon Maximum Size(Horizontal) | 200*100*500mm(H*D*W) |

| Warranty | 12 Months |

| After-Sales Service | Online Support |

| Prepayment | 30% |

| Weight | 3000kg |

| Headstock Feeding Stroke | 0~1500mm |

| Motor Rotating Speed | 2800rpm |

| Spindle Diameter | 30mm |

| Worktable Size | 510*340mm(W*H) |

| Maximum Worktable Tool Diameter | Sawing Blade: 350mm; Milling Tool: 300mm |

| Transport Package | 20gp |

| Specification | 5000*2100*2300mm |

| Trademark | Tianchen |

| Origin | Jinan. Shandong, China |

| HS Code | 8461409000 |

| Production Capacity | 200 Sets Per Month |

Product Description

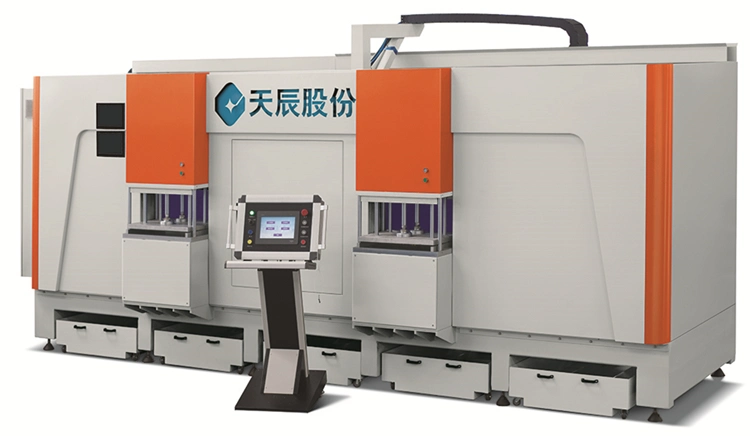

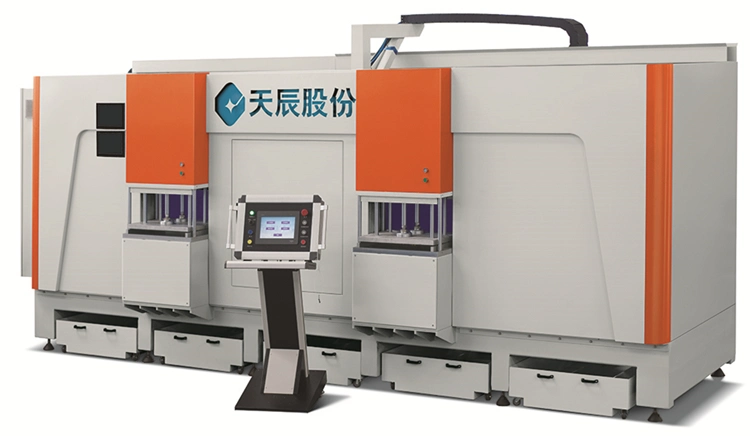

Aluminum Curtain Wall Automatic Tenon Milling Machine for Aluminum Facade Making Moudle LXD2S-CNC-300

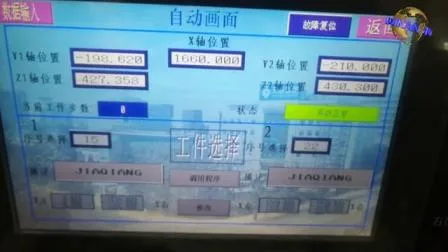

Machine Features☆Suitable for aluminum window door mullion profile's tenon and step surface's milling and sawing process. There aretwo motors for milling & sawing, one for horizontal milling, the other for vertical milling, applicable for milling variouskinds of mullion profiles' section with perfect versatility.☆Horizontally milling is accomplished by big power motor, with dual sawing blade or combined milling tool, to greatlyimprove the work efficiency. The connecting structure is new design, and tools can be changed very conveniently.☆Vertically cutting saw blade's angle is adjustable, with more wide applicable operation range.☆Two milling motors are 5 CNC axis servo controlled, no need manual adjustment, the operation can be done by fastand conveniently selecting the well preset program. Various section profiles can be processed continually.☆The feeding system adopts ball screw with large lead, moving faster and more stable.☆Ultra wide working table design, makes wider material clamping range.☆The feeding system adopts servo motor ball screw and linear guide rail structure, suitable for presetting differentmoving speed according to different thickness of profiles, with low vibration and high work accuracy.☆The servo motor adopts absolute pulse encoder, no need to come back to reference point after the machine powers on,the operation can be made by directly taking program.☆Real CNC servo system, convenient programming, with high compatibility, high efficiency and high reliability.

Technical Parameters

| Item | Specification |

| Milling Motor Power | 4.0kW+2.2kW |

| Motor Rotating Speed | 2800rpm |

| Spindle Diameter | 30mm |

| Headstock Feeding Stroke | 0~1500mm |

| Maximum Worktable Tool Diameter | Sawing Blade: ∮350mm; Milling Tool: ∮300mm |

| Worktable Size | 510*340mm(W*H) |

| Tenon Maximum Size(Horizontal) | 200*100*500mm(H*D*W)(∮300Sawing blade or milling cutter) |

| Tenon Maximum Size(Vertical) | 80*50*500mm(H*D*W)(∮300Sawing blade or milling cutter) |

| Contour Dimension | 5000*2100*2300mm |