Window Manufacturing Machines CNC Drilling and Milling Machine for Processing Round Holes, Slots, Keyhole of Aluminum Curtain Wall Machine

Overview Product Description Specification: 1.Suitable for milling, drilling, cutting and other processing processes of

Overview

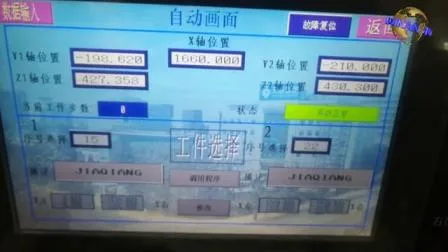

2.The table rotates at any angle of +90°~-90°, and multi-surface machining can be realized in one clamping.

3.Equipped with CAM software, the operation interface of the equipment is simple and intuitive.

4.Imported automatic tool change spindle, with 8-station tools magazine, can realize fast automatic tool change.

5.Double-zone design of workbench, clamping position automatic detection, automatic arrangement; High efficiency.

6.Fully closed design, equipped with Automatic Chip Conveyor, more safe to use, environmental protection.

7.The machine has QR code reader and Industrial PC, which can access to MES production management system and realize the automation of production.

8.Adopt high-precision linear guide rail, ball screw, rack and pinion and imported servo motor to ensure smooth movement and high positioning and processing accuracy.

Technical Parameter:

Spare parts details

Basic Info.

| Model NO. | WM4-CNC-3500 |

| Voltage | 380V |

| Spindle Power | 4.5kw |

| Operation Air Pressure | 0.6~0.8MPa |

| Tools Magazine | 8 Tools |

| Model | Wm4-CNC-3500 |

| Function | Milling, Drilling, Cutting |

| Name | Aluminum Four Axis CNC Machining Center |

| Transport Package | Wood Package |

| Specification | 5100x2100x 2250mm(LxWxH) |

| Trademark | windoormaker |

| Origin | China |

| HS Code | 847780000 |

Product Description

Product Description

Specification:

1.Suitable for milling, drilling, cutting and other processing processes of aluminum profile.2.The table rotates at any angle of +90°~-90°, and multi-surface machining can be realized in one clamping.

3.Equipped with CAM software, the operation interface of the equipment is simple and intuitive.

4.Imported automatic tool change spindle, with 8-station tools magazine, can realize fast automatic tool change.

5.Double-zone design of workbench, clamping position automatic detection, automatic arrangement; High efficiency.

6.Fully closed design, equipped with Automatic Chip Conveyor, more safe to use, environmental protection.

7.The machine has QR code reader and Industrial PC, which can access to MES production management system and realize the automation of production.

8.Adopt high-precision linear guide rail, ball screw, rack and pinion and imported servo motor to ensure smooth movement and high positioning and processing accuracy.

Technical Parameter:

| Power supply | Made to order |

| Spindle power | 4.5KW |

| Total power | 7.5KW |

| Rotary speed | 0-18000r/min |

| Operation air pressure | 0.6~0.8Mpa |

| Tools magazine | 8 tools |

| Worktable Height | 1000mm |

| Working range of X/Y/Z | X=3500mm,Y=200mm,Z=200mm 3850*200*200mm |

| axis feeding speed of X/Y/Z/A | X=0-60m/min,Y=0-30 m/min, Z=0-30 m/min,A=18r/min |

| Servo motor of X/Y/Z/A | 0.75KW/0.75KW/0.4KW/0.75kw |

| Positioning/repositioning accuracy | ±0.15mm/±0.05mm |

| Roughness | Ra6.3um |

| Specification of tool magazine | ISO30 |

| Dimension | 5100×2100×2250mm(LxWxH) |

| Weight | 4000kg |

| Machine name | Aluminum CNC Machining Center F our Axis WM-CNC-3500 | |

| Spare Parts Name | Brand(original) | Remarks |

| Low voltage electrical parts | Siemens(Germany) | AC Contactor/Circuit protector /Phase sequence protector |

| Switch button Electrical Parts | Siemens(Germany) | |

| Spindle | HSD(Italy) HSD | |

| Magnetic valve | Airtac(Taiwan) | |

| Cylinder | Airtac(Taiwan) | |

| PU Air Tube PU | SAMTAM(Japan) | |

| Square Guide Rail | ABBA/HIWIN (Taiwan) | |

| Reducer | Sejin(Korea)/APEX(Taiwan) | |

| Pneumatic components | Airtac(Taiwan) | |

| Servo Motor | YASKAWA(Japan) | |

| Driver | YASKAWA(Japan) | |

| CNC System | PA(Germany) PA | |

| Inverter | Delta(Taiwan) | |

Certifications

Company Profile

Jinan Windoormaker Machine CO., Ltd. Is an engineering company that has been in business for over 10 years which specialized in the manufacture and supply the UPVC & aluminum window and door machines.Windoormaker is a factory with cover area of 15000 m² . During the years developing, has made many devotes of machine improving, introducing new equipment and technology innovation for the production.

Machine at old customer

Packaging & Shipping

Send to us